Give me the sand faster!

We need to improve the performance of the entire production line. We have identified the performance of the grasper and gantry excavator as a bottleneck. Preliminary suggestions talk about the necessity of:

- purchasing a bigger gripping device (grasper),

- installing more powerful drives, to speed up extraction.

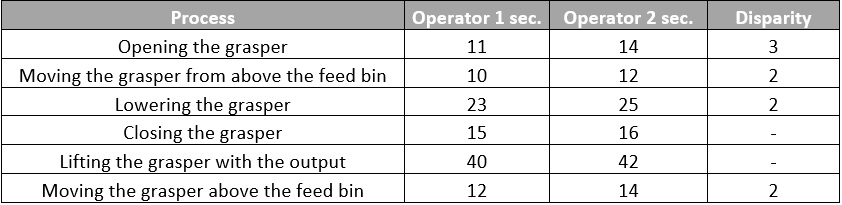

Following the concept of genchi genbutsu, ‘Go and see for yourself’, after day-long measurement and observations from the operator’s cabin, the stages of the extraction process have been identified together with their time in seconds (minimally repeatable times). Thanks to observations of two shifts, the measurements of two different operators’ work were obtained:

These clearly show that the first excavator operator was regularly performing all operations in a shorter time than his colleague from another shift. The next day, the results at the gemba were the same. This time, however, attention was paid to the differences between the excavator operators (the act of closing the grasper and lifting it with output was not taken into account, since it was recognized as being a specific activity dependant on the digging depth and the quality of the deposit). It turned out that the first excavator operator saved time by eliminating waiting times between operations (stabilization, dripping, the grasper achieving the maximum position). The disparities in seconds appear to be minimal, however, with regard to the actual number of cycles at the time of measurement, if the second excavator operator performs the actions in the same way as the first excavator operator, this would increase the performance of the excavator operator by 7% on his shifts.

Two root causes were identified:

- The second excavator operator hadn’t had enough training. His training covered only the technical aspects and safety rules. Nor was the experience of the first excavator operator was not used in his training – the second excavator operator didn’t have a chance to work with the first excavator operator in different weather conditions, in the daytime, with a different quality of deposits.

- Lack of standardized work, here meaning the sequence of actions and standard duration times necessary for effective and proper execution of tasks.

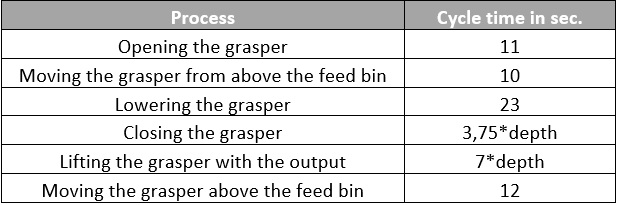

STANDARIZED WORK SHEET

For our case the standarized work sheet looks like below:

Elaboration of a standardized work flow serves to check whether the actions are being performed optimally. Thanks to that, we are able to immediately spot the problems. Moreover, we can measure progress and set goals to further improve performance. Without these measurements we would never notice the differences between the excavator operators.

Standardized work flows don’t serve to control the workers, but the processes. The workers themselves should periodically check whether they’re fulfilling the designated times and sequence. If their actual times are above or below the times set, they should undertake corrective measures. Yes, that’s not a mistake: according to the Lean concept, performing operations faster than set in the standard is a problem, since it indicates either an incorrect standard designation or overproduction, which causes significant waste and problems in subsequent steps of the process. The standardized work flow must be elaborated together with the operators and based on rigid and measurable guidelines, testing and repeatability. This will help avoid problems with complying with it.

The importance of adhering to standards is shown in the example of the Polish national football team under the leadership of Adam Nawałka. The team owes its results today to its coach, Nawałka, who set the standards for the actions to be performed after losing the ball – during games, the players repeatedly hear the famous words ‘Rebuild, rebuild!’ from the coach’s bench. This means that they should, as soon as possible, return to their fixed positions. Thanks to this, they’re ready to defend and know exactly where their teammates are located.

„The above atricle written by us (Leanhill) was published by “Maszyny i Surowce Budowlane” magazine in June 2016”

Leave a Reply